Quality

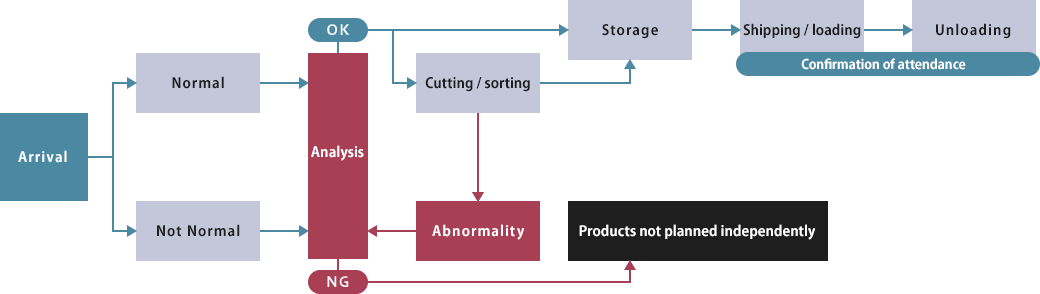

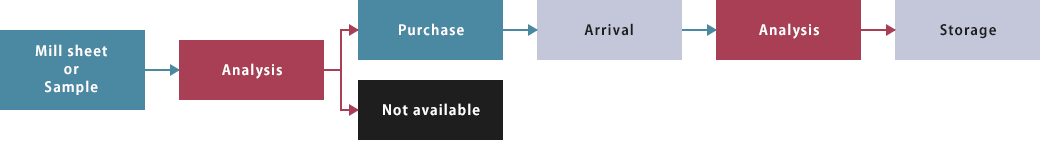

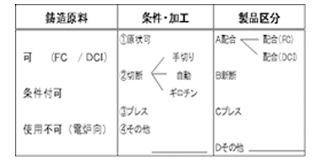

Casting raw material quality and composition control flow

Subscription item

New / irregularly purchased item

* 1. Abnormality detection

1.When an abnormal sound is generated at the time of disconnection

2.If the cutting plane is different from usual

3.Hard and hard to cut

4.When color, luster, rust are abnormal

* 2. Analysis

The analysis results are managed in the "Quality Analysis Ledger".

* 3. Confirmation of attendance

At the time of loading, the witness shall check whether foreign matter is mixed or not wet.

* 4. Visual check

The driver will check if there is any contamination or water contamination at the time of delivery, and submit a “shipment inspection report”.

Analysis flow

Flow Chart

flow.1

Arrival

flow.2

Sample collection

flow.3

Polish the sample with velder

flow.4

Analysis

flow.5

Judgment / control(quality analysis ledger)

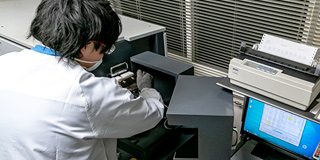

Introduction of Analysis Machines

Optical Emission Spectrometer

Optical Emission Spectrometer is an indispensable machine for a lot of steel industries and manufacturers to manage product quality since the machine can analyze elements in metals quickly and accurately. General citizens can use it after several days training. Uses argon gas.

*Example of elements that can be analyzed: B, C, Al, Si, P, S, Ca, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, Ce, W, Pb (22 elements)

X-ray Fluorescence Spectrometers

X-ray Fluorescence Spectrometers can analyze all elements from sodium (N) to uranium (U) qualitatively and quantitatively in a solid, powder, and liquid quickly and accurately without destroying them. Uses liquid oxygen.

*Example of elements that can be analyzed: Mg, Si, P, S, K, Pb, Mn, Cu, Zn, As, Br, Cd, Ag, Pt, Au, Hg

Portable X-ray Fluorescence Analyzer

Portable X-ray Fluorescence Analyzer can be used whenever you want since it is portable, although you cannot get lower tolerances with this. You need permission from the labor standard inspection office when you use it. Most suitable for classification of steels and non-ferrous.

*Example of elements that can be analyzed: Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ag, Sn, Sb, Hf, W, Ta, Re, Pb, Bi

Introduction of Radiation Detector